Methods of production of artificial sapphire

Our company "Rostox-N" is engaged in the production and processing of artificial sapphire for the needs of science and technology. We grow single crystals using three methods of crystallization from a melt: Stepanov (EFG), Kyropoulos and Czochralski. We will tell you more about them in our article.

Production of synthetic sapphire by the Stepanov method (EFG)

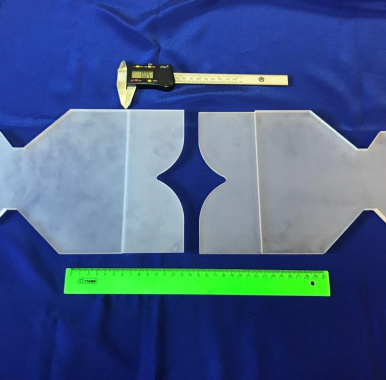

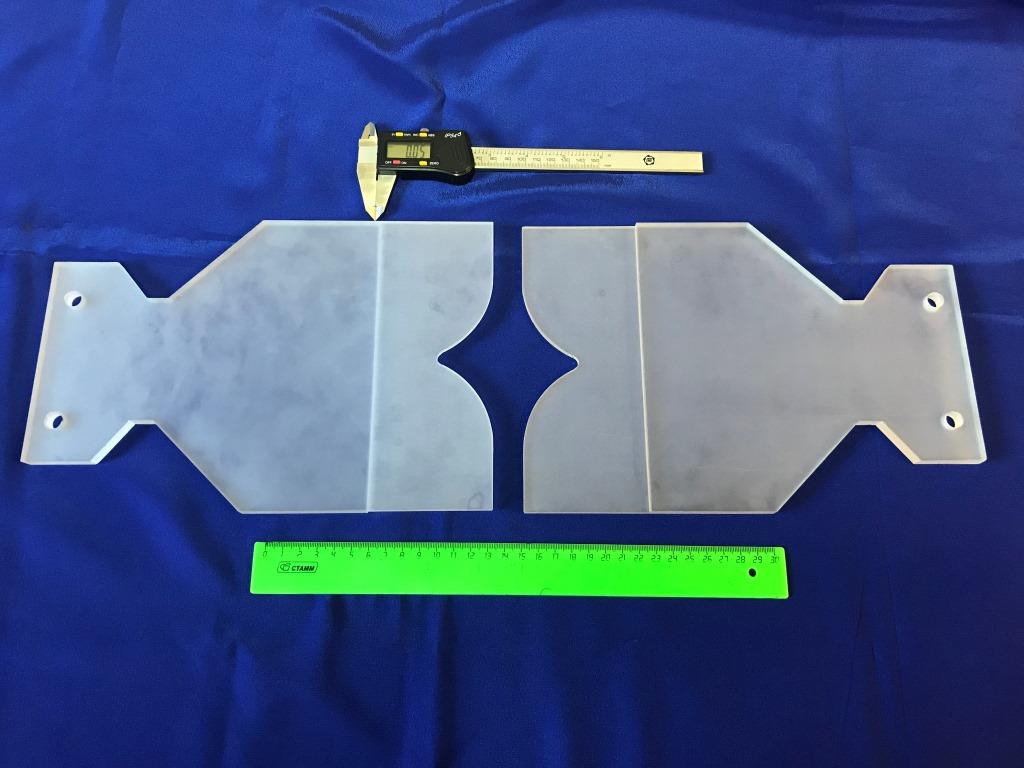

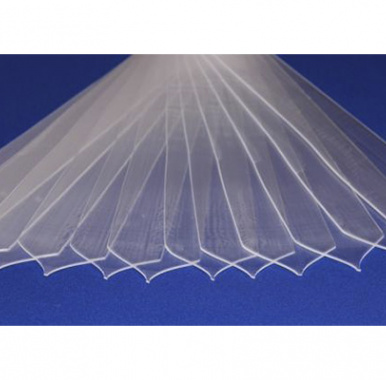

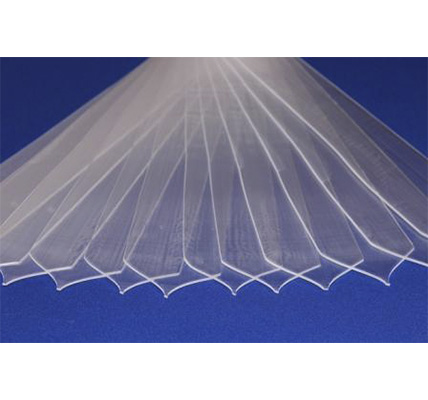

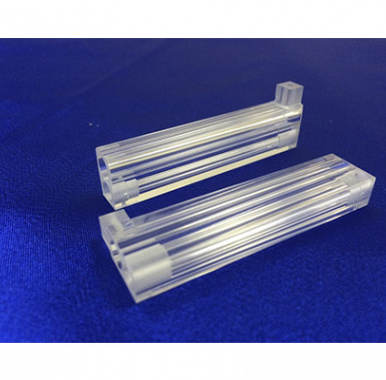

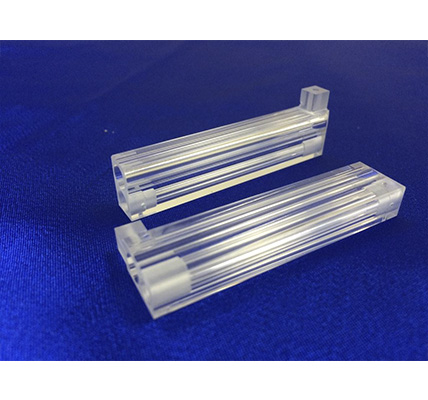

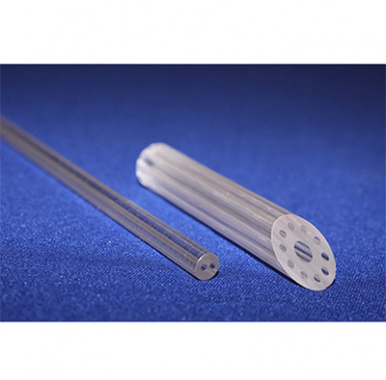

Since 1938, this method has been used to obtain many profiles of metal crystals, semiconductors and dielectrics of constant cross-section, as well as products of complex shapes. Due to the fact that the desired shape of the crystal is achieved directly during the crystallization process, the costs of additional processing are reduced to a minimum, which ultimately speeds up and reduces the cost of the artificial sapphire production process.

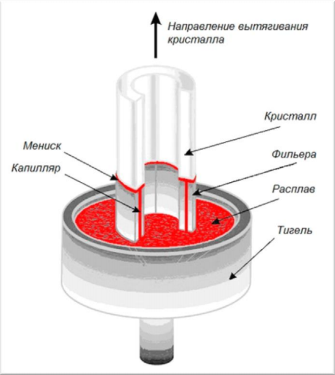

When the crystal grows, the melt flows from the crucible through capillary channels-spinneret of a special shaper to its working surface. It is these edges that define the contour of a thin layer of melt (meniscus), which is located between the working end of the shaper and the interphase boundary. What will be the cross-section of the stretched crystal depends on the geometry of the edges. When the optimal conditions of the thermal field are reached, the seed crystal contacts the liquid meniscus. The melt flows through the capillary channel to the surface of the shaper, crystallizing, forms the profile of the growing crystal, for example, a pipe, a plate, etc.

Advantages of the method:

-

high speed of cultivation;

-

low cost;

-

the length of the crystals is up to 700 mm.

Production of synthetic sapphire by the Kyropoulos method.

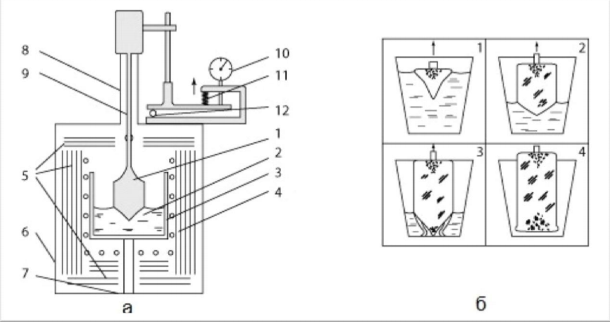

The Kyropoulos method has been used since 1926 to produce massive single crystals of 30-300 kg used in optical devices and other industries. The production of synthetic sapphire according to this method takes place in several stages:

-

The seed is fixed in a water-cooled crystal holder and is in contact with the melt located in the crucible.

-

The calculated parameters of reducing the temperature and the rate of drawing lead to the expansion of the crystal in the form of a hemisphere directly in the crucible.

-

As the crystal grows, it expands to the walls of the crucible, after which it rises several millimeters together with the crystal holder. Then the crystal grows again until the next growth reaches the walls of the crucible, the subsequent rise, etc.

-

To reduce internal stresses, the crystal is annealed for a long time directly in the growth equipment after the end of the growing process.

-

In the process of production by the Kyropoulos method, the diameter of single crystals can be more than 300 mm. In fact, only the size of the crucible sets the final limit.

Advantages of the method:

-

high purity of crystals (no worse than 99.995), which allows them to be used both in laser optics and in microelectronics

-

the possibility of manufacturing crystals of large diameters (more than 300 mm).

Figure a - shows the scheme of the equipment for growing crystals; Figure b - shows the growth stages.

Production of synthetic sapphire by the Czochralski method

The creation of the method dates back to 1916, when Professor Jan Czochralski accidentally dipped a pen into a crucible with molten metal. Instantly pulling out the pen, he found a crystallized ball.

Currently, the Czochralski method is used to grow not only crystals of metals and semiconductors, but also a number of refractory oxides: sapphires, rubies, some varieties of corundum, garnets, etc.

One of the main advantages of the method is to obtain crystals with a low level of internal defects.

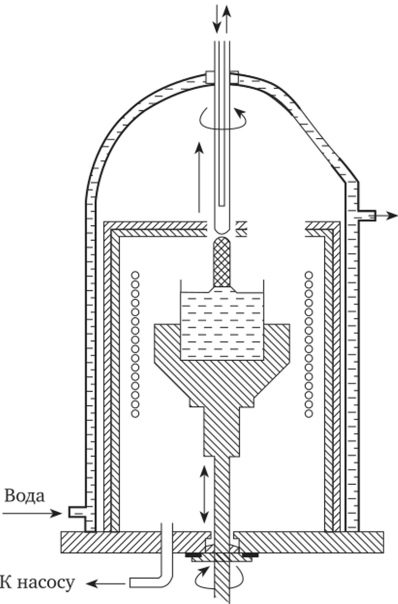

The single crystal is grown by the method of Czochralski by gradual extraction from the melt. In this case, the temperature of the melt is either constant or changes according to a certain law. Induction or resistive heating is used.

A modern equipment for growing artificial sapphire consists of the following elements

-

a tungsten or molybdenum crucible

-

thermal insulation;

-

a device for creating a vacuum or an inert gas;

-

a device for rotating and pulling the crystal;

-

a mechanical, optical or electronic system for regulating the process.

Advantages of the method:

-

the possibility of introducing alloying additives and obtaining colored crystals;

-

obtaining crystals with a low level of internal defects.

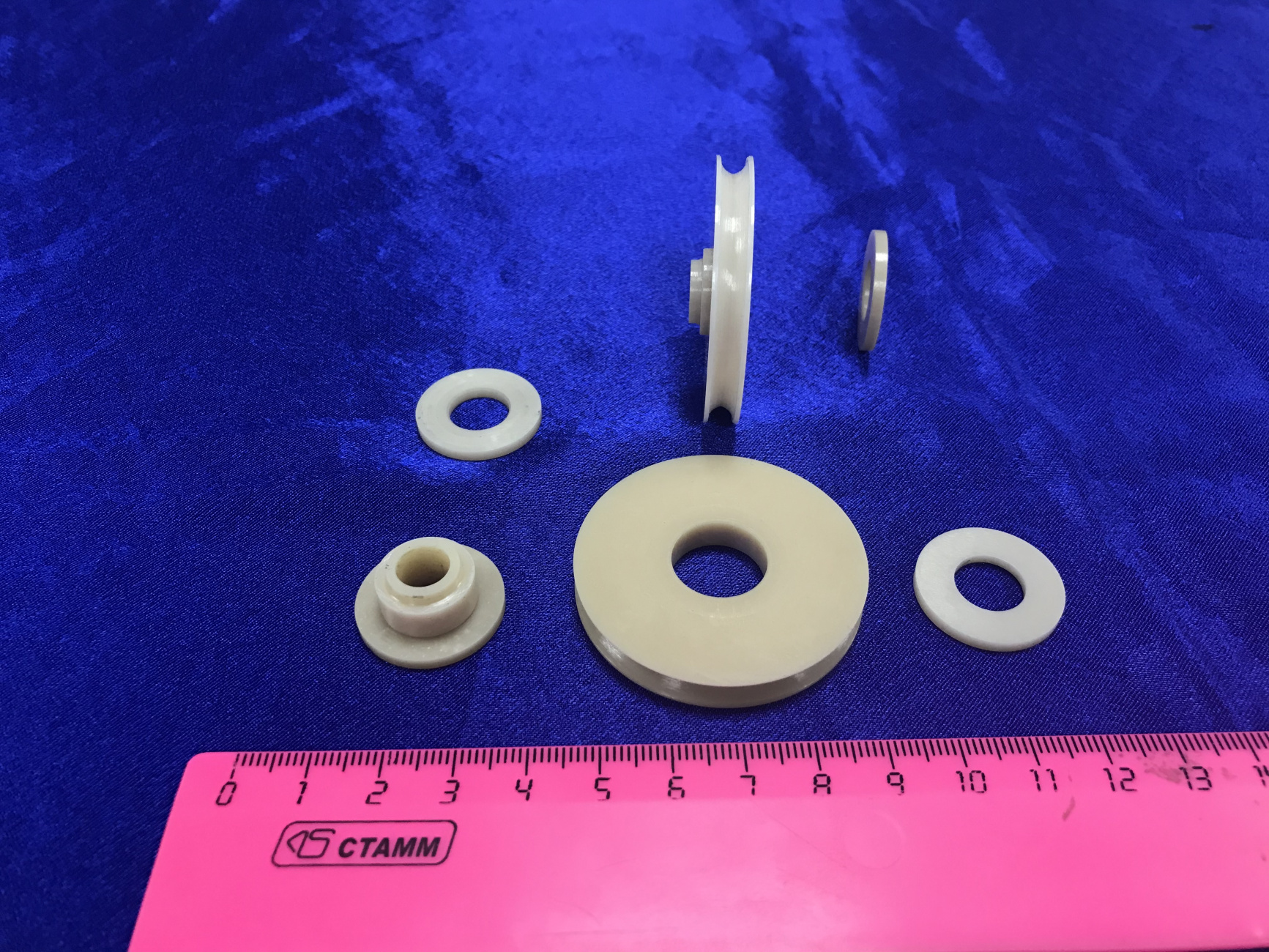

At the moment, our company produces crystals by the Czochralski method with a diameter of up to 50 mm, a length of up to 200 mm; Cyropoulos weighing up to 100 kg (with a diameter of up to 300 mm), and Stepanov's method – crystals in the form of ribbons, tubes and rods up to 700 mm long. Depending on your needs, we can offer crystals produced in different ways.

For additional consultations, you can contact our experts: call +7 (496) 527-35-91 or write to us by e-mail info@rostox-n.ru.